Fixing of the sole to the shoe: all methods to join the bottom to the upper

Fixing of the sole to the shoe here are main methods

The fixing is one of the most important step leading to the creation of quality men's shoes. There are different ways to fix the sole to the upper. Here are the main:

Fixing with pasted sole/strong>

In the past the upper was fixed to the leather insole - with “littleway” hooks and then the sole was pasted with neoprene or similar materials. Nowday this system is unusual and the shoe is directly pasted during lasting process using thermal adhesive, without “littleway” hooks.

Fixing with Ideal construction

It’s the most simple method to sew upper and sole. Upper edges are turned outwards, outside the last and sew externally. The upper is pasted to theleather middlesole and then stitched to the outsole.

Fixing with Goodyear welt construction

The upper and the leather insole (in this case it’s a leather middlesole with a particular channeling.) are sewing with a flat seam to the welt by a special machine with a curved needle. Between leather middlesole and tangent line to welt there’s a cork filling. The mid-sole is then sewed to the welt. In this construction both welt and sole are not pre-finished, but the excess on the edges will be trimmed and finished later. To avoid the sewing breaking, a grooving covers the second seam (it’s a channeling 1mm wide and 2-6mm deep from the sole edge) or a fastened insole rib ( an high precision machine channels under the sole, then the sole is seamed, an adhesive is applied and the relieved edge by the channel is closed and leveled). In Goodyear construction with border welt, instead of sewing welt, the outsole is only sticked on the welt.

Fixing with Blake construction

A chain stitch seams the outsole, the upper and the leather insole. Sometimes could be used also “littleway” hooks (which are not visible on the leather insole) and an overcast stitch instead of chain stitch, which increases shoes flexibility and resistance.

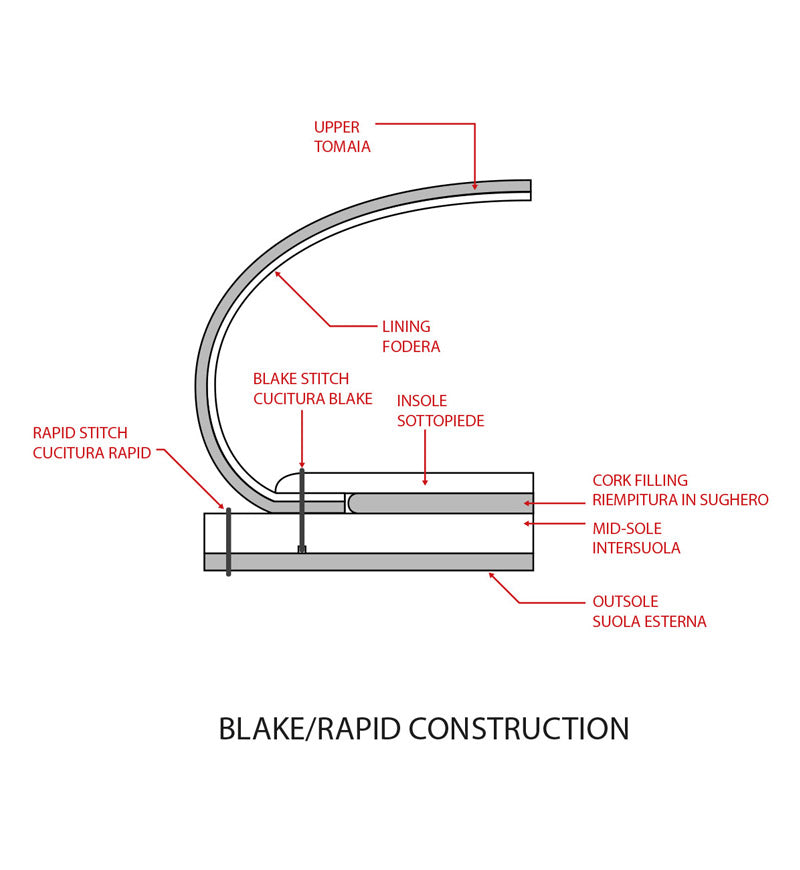

Fixing with Blake Rapid construction

Once the shoe is on the last, the first sole (leather middlesole) is applied and it is stitched by blake sewing machine to the insole leather and to the upper in calf leather . A first adhesive is smeared on leather middlesole and lasted shoe. The shoe is pressed by the sole cementing machine , then before blake sewing the last is slipped. The blake sewing sews the leather insole and the leather middlesole and it is visible inside the shoe. The shoe is put on the last again and a second adhesive is spreaded on leather middlesole and sole. A rubber or leather sole is applied, then the shoe is pressed again by the sole cementing machine and the sole is roughed round. The rapid sewing machine sews the second sole or leather treadsole to the leather middlesole. If the shoe has a welt, the rapid sewing machine inserts and sews it. The rapid seam is clearly visible on the welt and the bottom of the sole. If the shoe hasn’t a welt, it is visible only on the bottom of the sole. The structure of the welt with the leather middlesole guarantees the shoes will fit the foot perfectly and an excellent air permeability. The double stitched Blake-Rapid shoes has got the advantage to guarantees the best possible imperviousness to water and durability of the bottom and also the possibility to be easily resoled. Almost all Franceschetti shoes are sewn with the traditional Blake Rapid method, especially handmade shoes with structured bottom in leather or rubber. The fixing of the sole with AGO method, that is to say by gluing, is used by the company only for some sporty shoes with rubber sole.